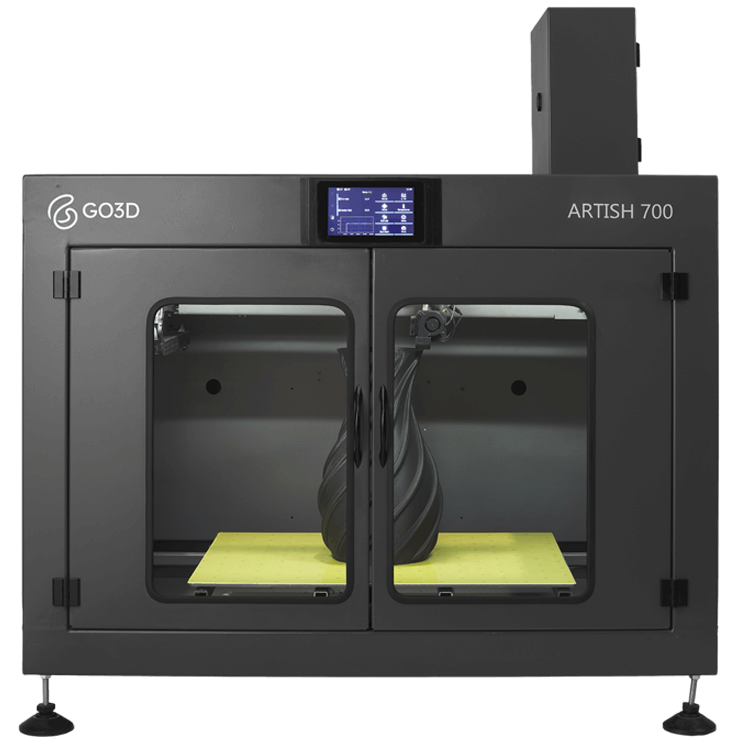

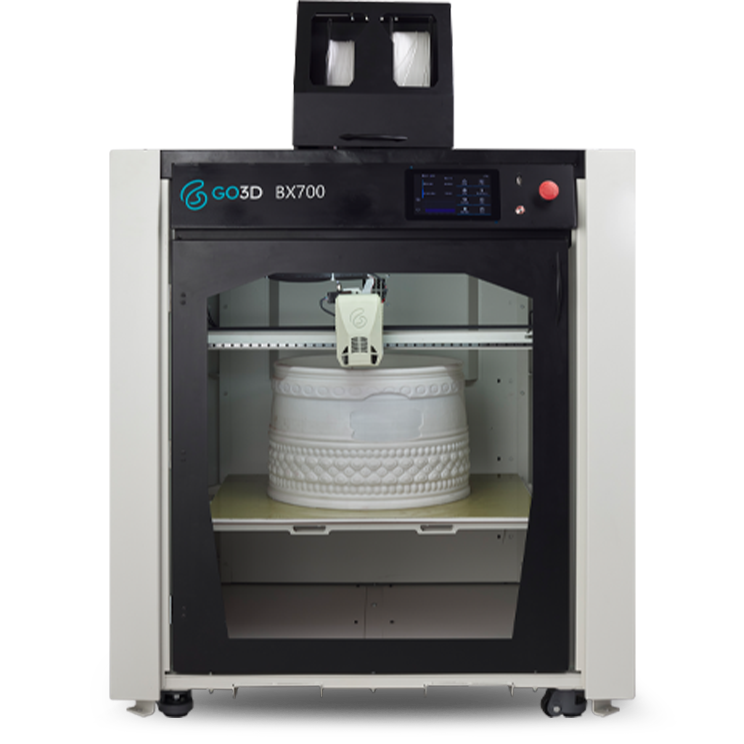

BX 700

Built for Big Ideas and Prints

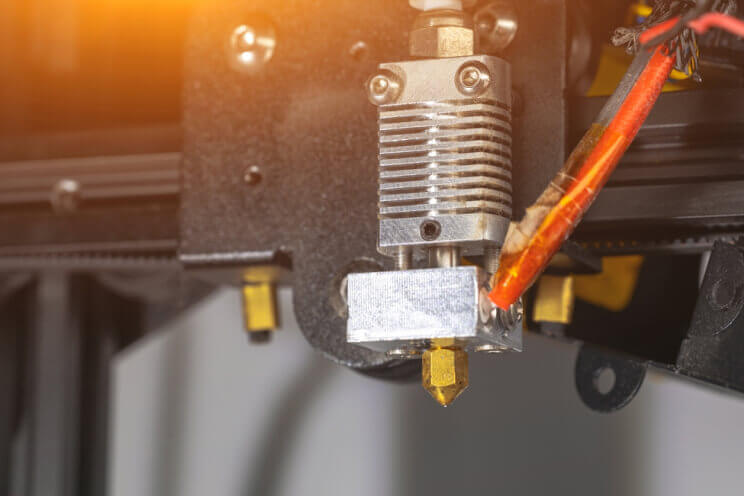

Engineered for high-speed, large-format 3D printing, the BX 700 is for professionals who need consistent output. With a direct drive extruder system, intuitive web-based controls, and an integrated camera, it delivers dependable, high-volume results.

Request Quote

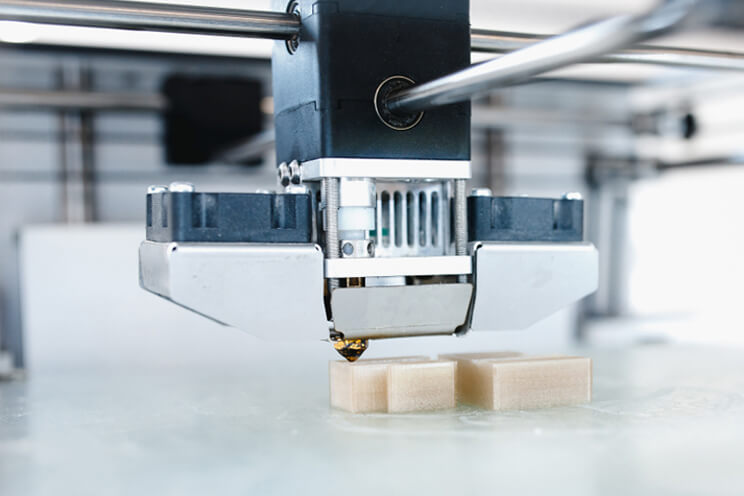

Large Format with High Speed

Heavy-duty build for continuous production, up to 4 kg/day output

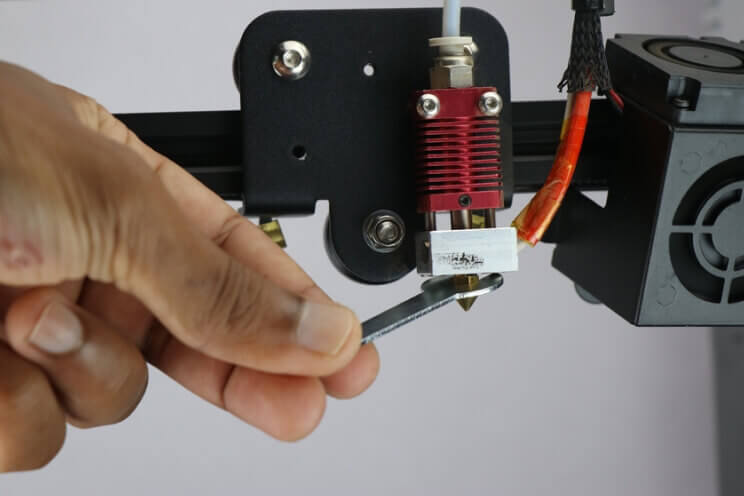

Finger Swappable Nozzle

Effortlessly change nozzles without tools for different materials

Anti-clog Nozzle Technology

Minimises nozzle blockage to ensure uninterrupted, smooth printing

Intelligent Material Sensing

Detects when the material gets stuck and stops printing to avoid damage and ensure smooth operation

Purpose Built for Performance

Printer Properties

| Build volume | 700 (X) * 500 (Y) * 500 (Z) mm |

|---|---|

| Print head | Single Extrusion Print Head |

| Extruder type | Dual Metal Gear Direct Drive - All Metal Extruder |

| Filament diameter | 1.75 mm |

| Nozzle diameter | Swappable 0.4 mm by default (0.6/0.8/1.0/1.2/1.4 mm compatible) Effortless nozzle swap at ambient temperature |

| Layer thickness | 100 - 300 micron with 0.4 mm nozzle 200 - 400 micron with 0.6 mm nozzle 200 - 600 micron with 0.8 mm nozzle 300 - 700 micron with 1 mm nozzle 300 - 800 micron with 1.2 mm nozzle 400 - 1000 micron with 1.4 mm nozzle |

| XYZ Precision | X - 12.5, Y - 12.5, Z - 2.5 microns |

| Print accuracy | ± 250 microns or 0.002 mm per mm of dimensions (whichever is higher) (This accuracy is with 0.4 mm nozzle and 0.2 mm layer height) |

| Print speed | 25 - 120 mm/s (Adjustable based on material, nozzle size, layer height and part geometry) |

| Print head travel speed | Up to 150 mm/s |

| Build plate | Specialised sheet with glass fibre |

| Build plate temperature | Up to 120 °C |

| Supported materials | PLA, TPU, PETG, ABS, ASA, PA, PC, PLA CF, PETG CF (Carbon fibre) |

| Nozzle temperature | Up to 300 °C |

| Connectivity | USB port, WiFi, Ethernet |

| Power requirements (input) | 100 - 240V AC, 50-60Hz |

| Ambient conditions (Operating ambient temp) | 15 - 40 °C, 10 - 90% RH (non-condensing) |

Software

| Supplied software | Go3D Transform |

|---|---|

| Other supported slicer software | Cura, Simplify 3D |

| Supported OS | macOS, Windows and Linux |

| File types | STL, OBJ |

| Machine code | GCODE |

Features

Fail Safe Print Recovery

Automatically resumes printing after power loss or interruptions to prevent failed prints

Dual Filtration System (Hepa+Carbon)

Advanced filtration removes harmful particles and odors for safer, cleaner operation

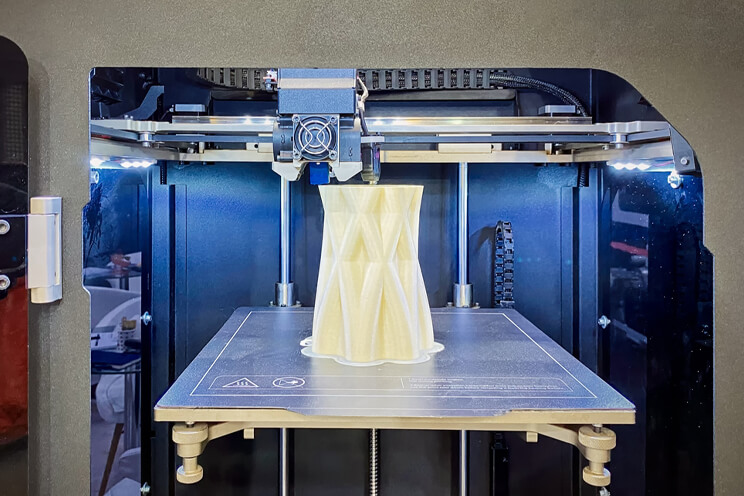

Auto Bed Leveling

Automatically adjusts the printing platform's height across various points to ensure a consistent distance between the nozzle and the bed

Web-Based Control Interface

Manage and monitor your printer remotely from any device via a user-friendly web interface

Filament Runout Detection

Detects when filament runs out and pauses printing automatically to prevent incomplete prints and wasted materials

Z-motion Platform

Precision-engineered Z-axis movement ensures accurate layer positioning for superior print results

Silicon Heat Bed

Heats up fast and evenly so that prints stick well and don’t curl or lift at the edges

Integrated Camera for Remote Monitoring

Real-time video feed lets you remotely view and monitor your prints from anywhere

Applications

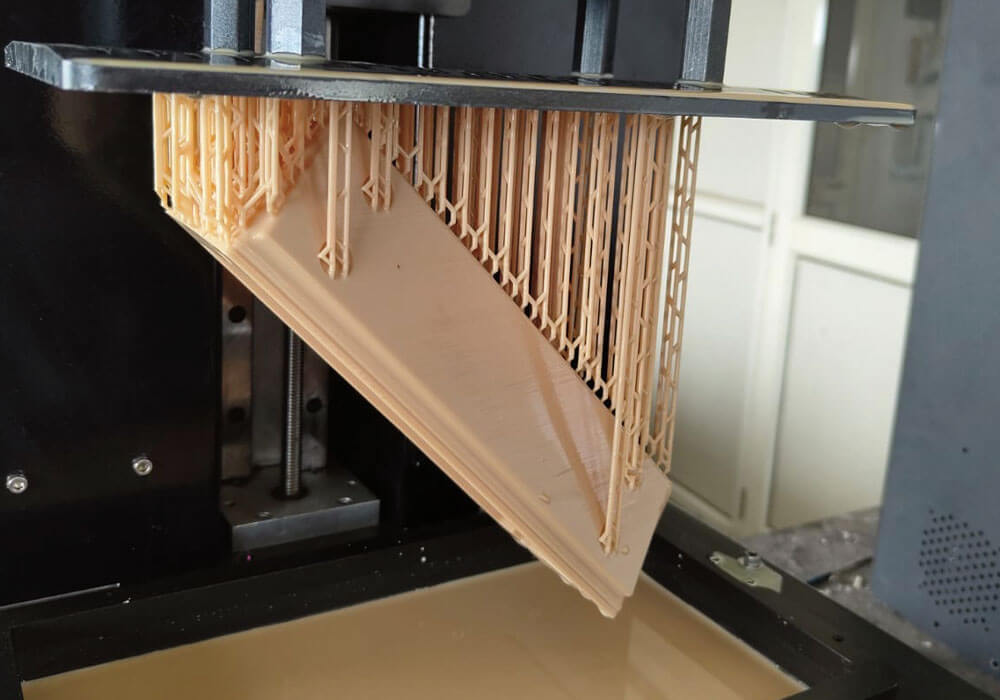

- Rapid Prototyping

- Rapid Tooling

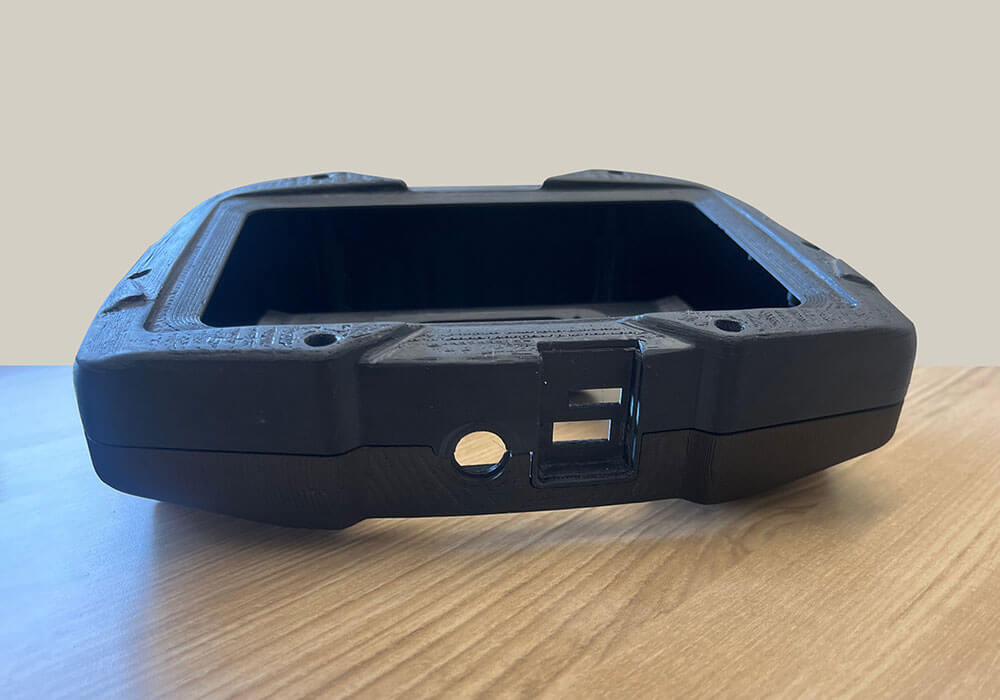

- Jigs & Fixtures

- End-use Parts

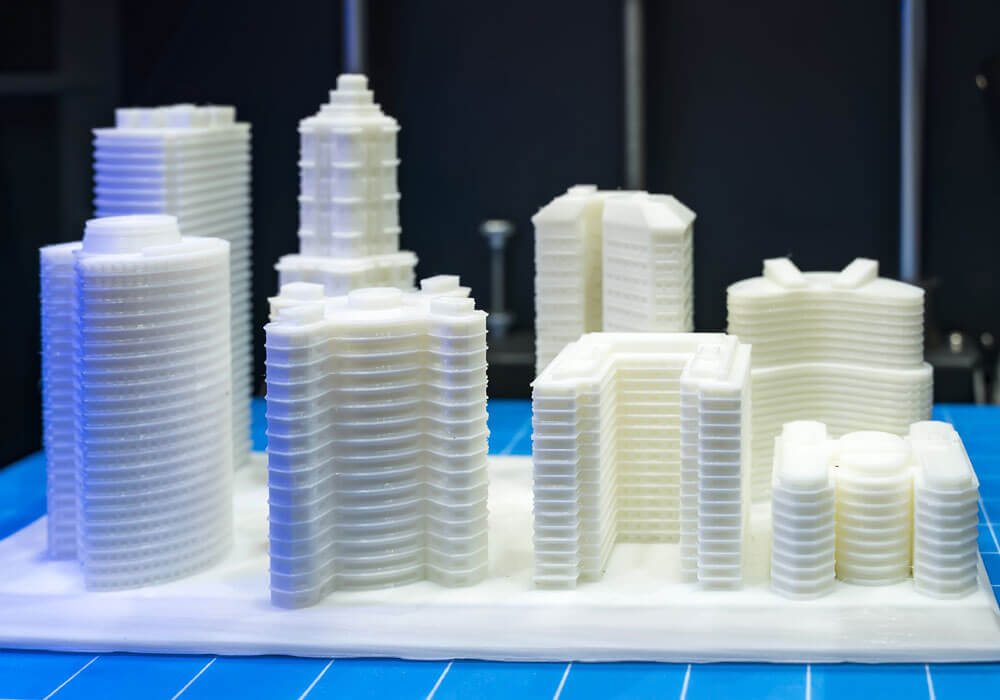

- Architectural Models

- Sand & Investment Casting

- Educational Aids

- Electronics / IoT Housing