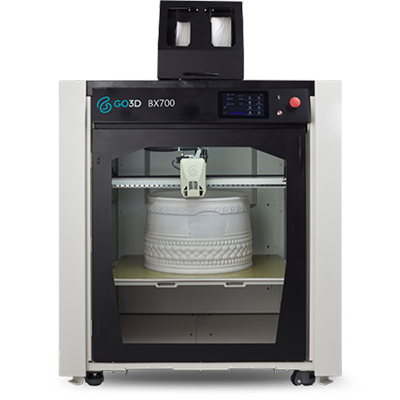

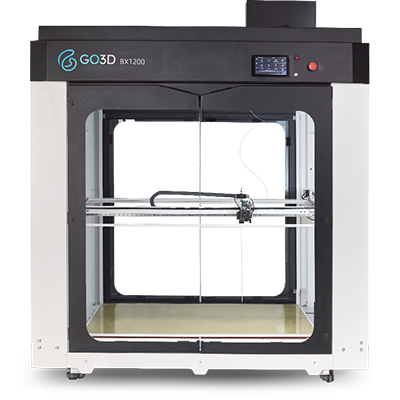

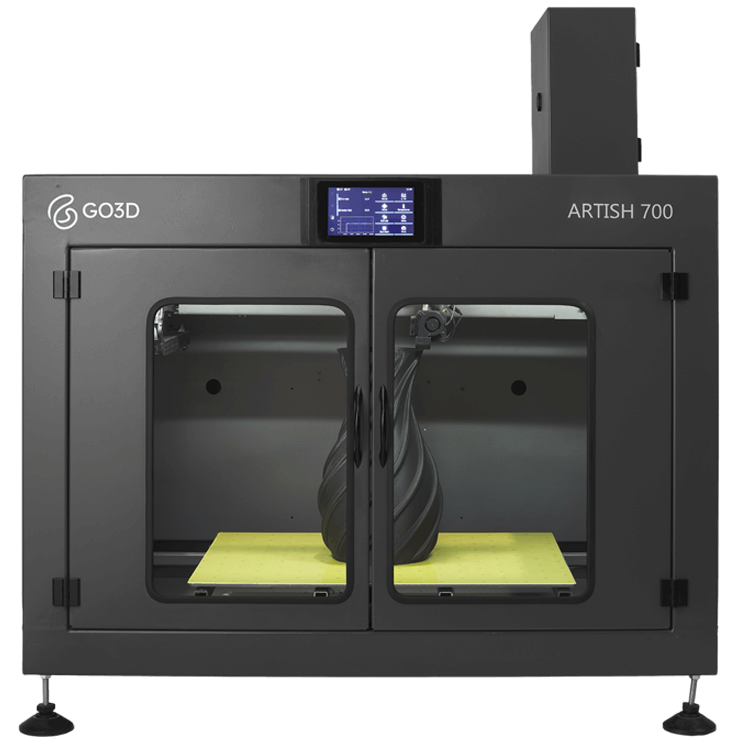

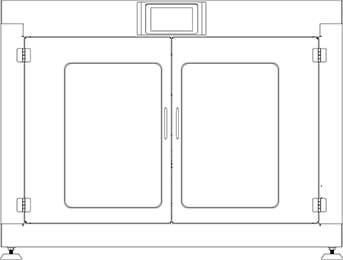

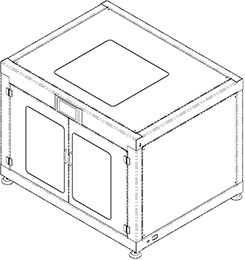

Artish 700

Production-Ready Powerhouse

Designed for round-the-clock performance, the Artish 700 combines strength, stability, and speed. With a generous build volume and advanced features, it’s a true workhorse for production environments.

Request Quote

Lorem aepsum dolor asmnet consectetur adipiscin elit.

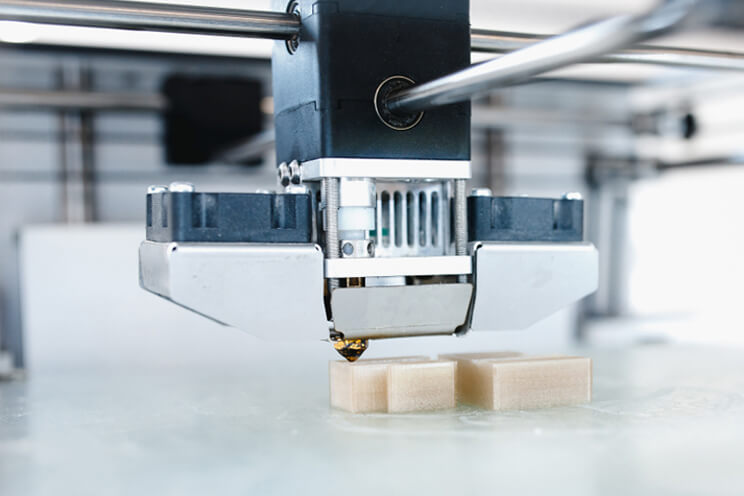

Large Format Printing

Built for big ideas, handles large-scale prints for nonstop production

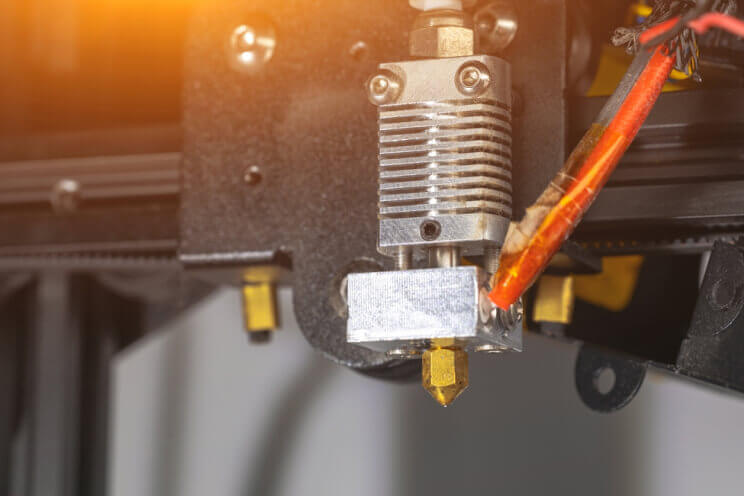

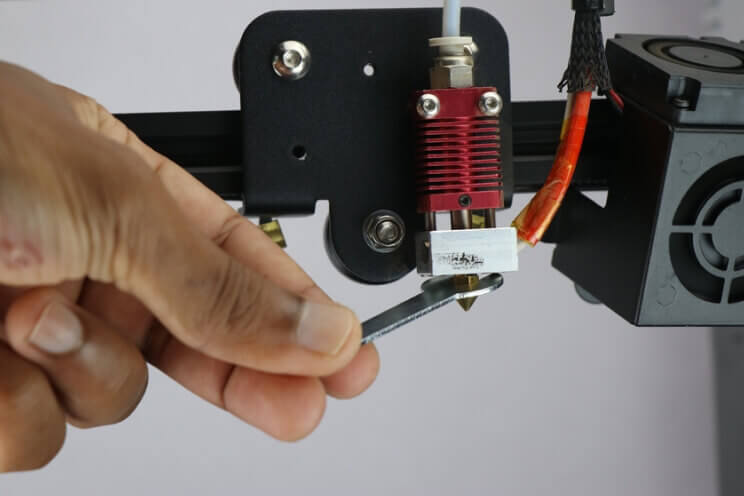

Finger Swappable Nozzle

Change nozzles effortlessly; no tools needed for quick swaps

Anti-clog Nozzle Technology

Prevents blockages so printing remains smooth and maintenance-free

Intelligent Material Sensing

Detects when the material gets stuck and stops printing to avoid damage and ensure smooth operation

Built for Speed

Backed by Reliability

Printer Properties

| Build volume | 700 (X) * 500 (Y) * 500 (Z) mm |

|---|---|

| Print head | Single Extrusion Print Head |

| Extruder type | Dual Metal Gear Direct Drive - All Metal Extruder |

| Filament diameter | 1.75 mm |

| Nozzle diameter | Swappable 0.4 mm by default (0.6/0.8/1.0/1.2/1.4 mm compatible) Effortless nozzle swap at ambient temperature |

| Layer thickness | 100 - 300 micron with 0.4 mm nozzle 200 - 400 micron with 0.6 mm nozzle 200 - 600 micron with 0.8 mm nozzle 300 - 700 micron with 1 mm nozzle 300 - 800 micron with 1.2 mm nozzle 400 - 1000 micron with 1.4 mm nozzle |

| XYZ Precision | X - 12.5, Y - 12.5, Z - 2.5 microns |

| Print accuracy | ± 250 microns or 0.002 mm per mm of dimensions (whichever is higher) (This accuracy is with 0.4 mm nozzle and 0.2 mm layer height) |

| Print speed | 25 - 120 mm/s (Adjustable based on material, nozzle size, layer height and part geometry) |

| Print head travel speed | 25 - 150 mm/s |

| Build plate | Specialised sheet with glass fibre |

| Build plate temperature | Up to 120 °C |

| Supported materials | PLA, TPU, PETG, ABS, ASA, PA, PC, PLA CF, PETG CF (Carbon fibre) |

| Nozzle temperature | Up to 300 °C |

| Connectivity | USB port |

| Power requirements (input) | 100 - 240V AC, 50-60Hz |

| Ambient conditions (Operating ambient temp) | 15 - 40 °C, 10 - 90% RH (non-condensing) |

Software

| Supplied software | Go3D Transform |

|---|---|

| Other supported slicer software | Cura, Simplify 3D |

| Supported OS | macOS, Windows and Linux |

| File types | STL, OBJ |

| Machine code | GCODE |

Features

Auto Bed Leveling

Automatically adjusts the printing platform's height across various points to ensure a consistent distance between the nozzle and the bed

Filament Runout Detection

Detects when filament runs out and pauses printing automatically to prevent incomplete prints and wasted materials

Silicon Heat Bed

Heats up fast and evenly so that prints stick well and don’t curl or lift at the edges

Dual Z Axis Stability

Two side stepper motors keep the Z-axis stable for precise, consistent layer alignment and better print quality

Applications

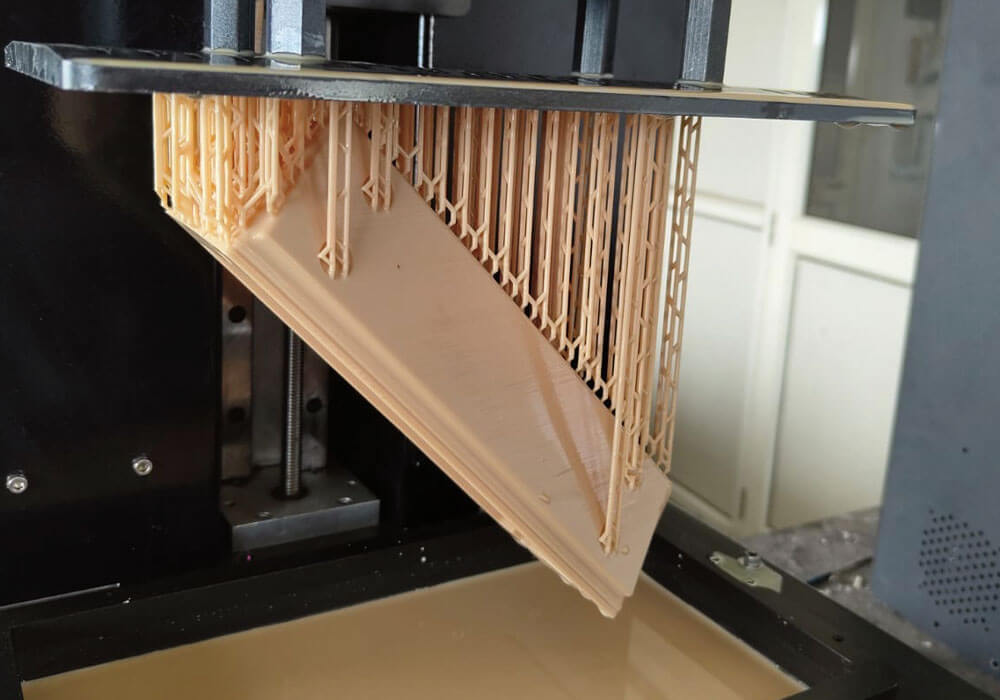

- Rapid Prototyping

- Rapid Tooling

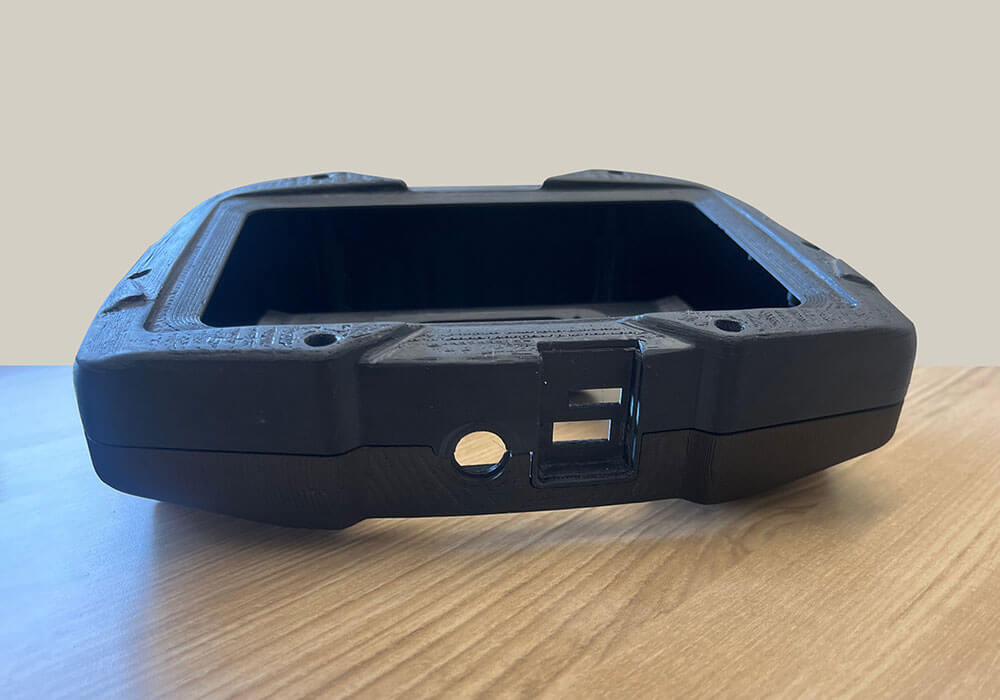

- Jigs & Fixtures

- End-use Parts

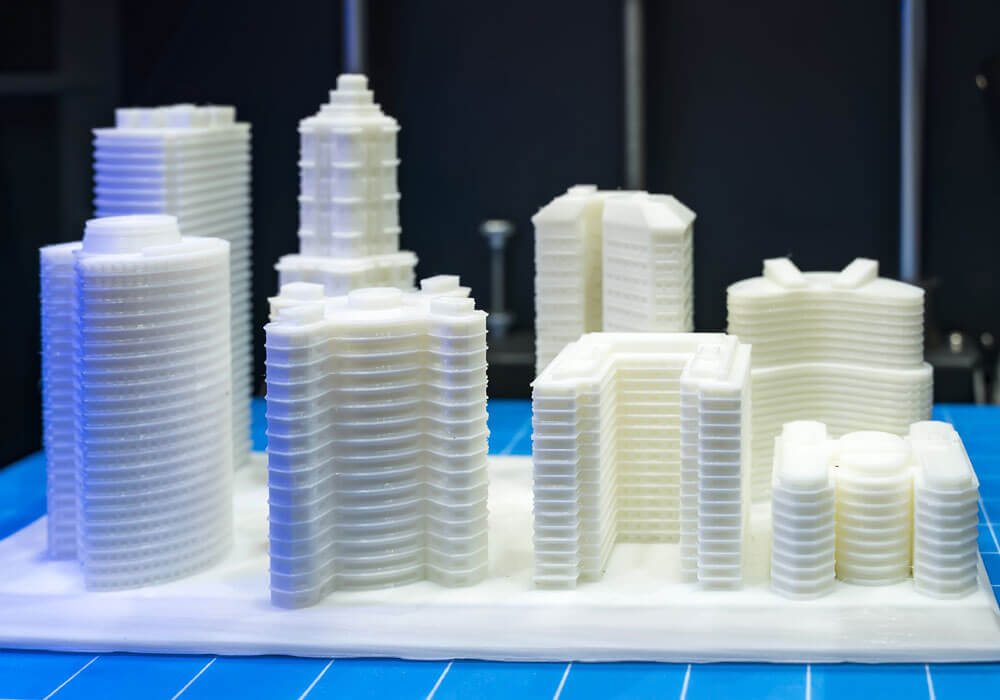

- Architectural Models

- Sand & Investment Casting

- Educational Aids

- Electronics / IoT Housing